Unveiling the Ultimate Secret behind the Angle Grinder Shutdown!

Angle grinders are versatile power tools used in many industries and workshops. However, one common issue that users often face is unexpected shutdowns during operation. These shutdowns can be frustrating and impact productivity. In this article, we will delve into the ultimate secret behind the angle grinder shutdown and provide practical tips to prevent and troubleshoot this issue.

Causes of Angle Grinder Shutdown:

Understanding the causes of angle grinder shutdown is crucial to effectively address the issue. Here are some common reasons why your angle grinder may unexpectedly shut down:

- Overloading: Overloading the grinder with excessive pressure or workload can cause overheating and trigger a shutdown to prevent damage.

- Electrical Issues: Faulty wiring, damaged plugs, or issues with the power source can lead to sudden shutdowns.

- Motor Problems: A malfunctioning motor, worn-out brushes, or internal issues within the motor can cause the grinder to shut down unexpectedly.

- Thermal Overload: Continuous operation without allowing the grinder to cool down can trigger a thermal overload shutdown to protect the tool.

- Dust and Debris: Accumulation of dust and debris in the grinder’s vents and components can obstruct airflow and cause overheating.

Preventing Angle Grinder Shutdown:

Now that we’ve identified the common causes of angle grinder shutdown, let’s explore practical tips to prevent this issue and ensure smooth operation:

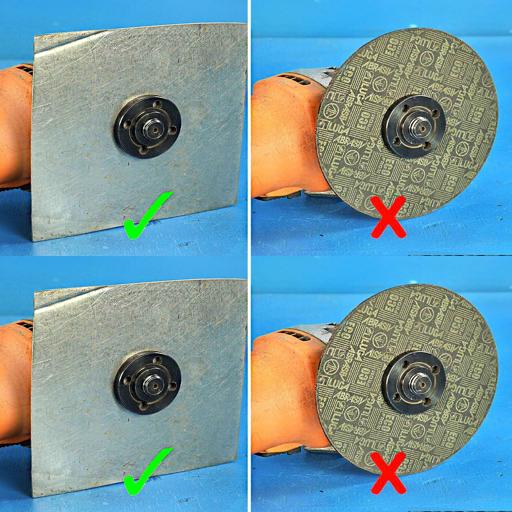

- Use the Right Disc: Ensure you are using the correct type and size of the grinding disc for the job to prevent overloading the grinder.

- Monitor Load: Avoid applying excessive pressure or force on the grinder while in operation to prevent overload and overheating.

- Maintain Proper Ventilation: Keep the grinder’s vents clean and free from dust and debris to ensure optimal airflow and cooling.

- Allow for Cooling: Take breaks during extended use to allow the grinder to cool down and prevent thermal overload shutdowns.

- Check Electrical Connections: Regularly inspect the power cord, plug, and power source for any damage or issues that may lead to shutdowns.

Troubleshooting Angle Grinder Shutdown:

If you experience an unexpected shutdown with your angle grinder, here are some troubleshooting steps you can take to identify and resolve the issue:

- Check for Overheating: Feel the grinder’s body for excessive heat, which may indicate overheating. Allow the tool to cool down before attempting to use it again.

- Inspect Motor: Check the motor for any signs of damage, wear, or abnormal sounds that may indicate a motor problem. Consult a professional if needed.

- Clean the Grinder: Remove any dust or debris from the grinder’s vents and components using a brush or compressed air to improve airflow.

- Reset Thermal Overload: If the grinder has a thermal overload protection feature, allow it to cool down and reset before restarting.

- Test in Different Outlet: Plug the grinder into a different power source to rule out electrical issues with the original outlet.

By following these preventive measures and troubleshooting tips, you can unveil the ultimate secret behind the angle grinder shutdown and ensure efficient and uninterrupted operation of your power tool. Remember to prioritize safety and proper maintenance to prolong the lifespan of your angle grinder and prevent unexpected shutdowns.

#SummerBeauty #DIYHacks #FashionTips #BeautyHacksByBlossom

#SummerBeauty #DIYHacks #FashionTips #BeautyHacksByBlossom